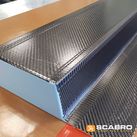

Biotex Twill 200

Lightweight high performance fabric for sporting goods and decorative applications 200g/m²

Biotex Flax provides high levels of performance, coupled with the ease of processing normally associated with glass-reinforced materials. The materials use low-twist technology to provide a combination of sustainability, performance and processability not previously seen in composites. Compared to glass fibre composites, Biotex Flax offers reduced weight, improved environmental impact, vibration damping, similar specific stiffness and safer handling.

Biotex Flax is available in a range of yarn weights and fabric constructions. The materials can be processed using standard composites manufacturing techniques and are suitable for semi-structural and decorative applications in a range of sectors, including automotive, sports & leisure, consumer goods and construction.

Biotex Flax 200g/m² 2×2 Twill fabric is typically used for lightweight and decorative applications in sporting goods, consumer goods and automotive interiors.

Specification

- Weave Style: 2x2 Twill

- Fabric Weight: 200 g/m²

- Width: 1500 mm - others on request

- Typical Ply Thickness: 0.25-0.4 mm, depending on process

Processing

- Fibre Volume Fraction: 31%

- Density: 1.29 g/cm³

- Tensile Modulus: 12 GPa (ISO 527-4)

- Tensile Strength: 106 MPa (ISO 527-4)

- Elongation: 1.5% (ISO 527-4)

- Flexural Modulus: 9.1 GPa (ISO 14125)

- Flexural Strength: 121 MPa (ISO 14125)

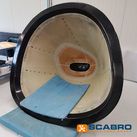

Case Study:

Environmentally-Friendly Surfboard

Background

Performance: Biotex Flax can be used in the same way as carbon fibre or fibreglass, meaning that once supplied Samsara could construct the eco-surfboard without having to change their existing process. Once constructed the board was tested extensively with excellent results.

Geen producten in deze categorie

Laatste Nieuws

-

Vacatures en stageplaatsen11/11/2023

-

Schade-inspectie van composieten09/11/2022

-

Focus on Thermoforming14/08/2021

-

Naadloze epoxypasta modellen02/11/2020