Prepregs

Prepregs

Snelle ontwikkeling en productie van high-tech prepregs.

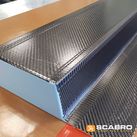

Het Britse SHD is in 2011 opgericht en is in korte tijd gegroeid naar een fabrikant met 5 prepreg productielijnen en 80 ervaren medewerkers. De epoxy formulaties zijn gebaseerd op decennia lange kennis van behoeftes van de markt. Zo zijn lange out-times en lage cure temperaturen in combinaie met een snelle doorharding mogelijk. De combinatie van deze technologisch hoogwaardige harsen in combinatie met korte levertijden van 2-3 weken maakt van SHD de meest concurrende en snelst groeiende prepreg fabrikant van Europa.

Onze tooling-prepreg epoxyharsen kunnen worden geleverd in combinatie met een breed programma weefsels. Wij leveren kleine hoeveelheden, vanaf 10m, met zeer korte levertijden van 2-3 weken. Verpakking, loggers verzending, alles is mogelijk. Welkom bij de meest flexibele prepreg fabrikant waar u ooit mee heeft gewerkt!

Scabro is importeur van SHD prepregs uit Groot Brittannië sinds 2015.

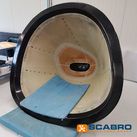

SHD in Action...

SHD in Action...

SHD Composite Materials Ltd are at the leading edge of advanced composites technology. We manufacture a wide range of Thermoset Prepregs, which include carbon, glass, aramid, natural and hybrid fabrics, whilst also offering a toll impregnation service.

SHD Composites are proud to co-sponsor the exciting Bloodhound SSC project. Bloodhound is a supersonic car attempting to break the world land speed record by reaching an incredible 1000 mph!

Find out more

www.bloodhoundssc.com

Our Ethos...

SHD Composite Materials Ltd, Leaders in Composite Materials through Service, Quality and Innovation

To prioritise customer satisfaction as a key business principle and to differentiate us from our competitors.

Everyone at SHD will work together to achieve this aim to ensure the future growth and success of the company.

About Us

SHD Composites is a fast growing company led by Steve and Helen Doughty. Our management team have many years of experience in the manufacturing of prepregs, enabling us to provide first class technical support in everything we do.

Working in dynamic partnership with our clients, we offer exceptional levels of service and flexibility. This, coupled with a wealth of experience within the composite industry, ensures that we provide high quality core materials, whilst having the understanding and ability to develop bespoke products to suit individual client needs.

We operate two fabric lines and one unidirectional laminating line. These bespoke machines were designed in-house to exacting specifications to give the highest possible quality materials.

Laatste Nieuws

-

Vacatures en stageplaatsen11/11/2023

-

Schade-inspectie van composieten09/11/2022

-

Focus on Thermoforming14/08/2021

-

Naadloze epoxypasta modellen02/11/2020