Vlas

Biotex Flax: High performance, lightweight alternative to glass and carbon fibres.

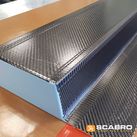

Biotex Flax provides high levels of performance, coupled with the ease of processing normally associated with glass-reinforced materials. The materials use a unique twistless technology to provide a combination of sustainability, performance and processability not previously seen in composites. Compared to glass fibre composites, Biotex Flax offers reduced weight, improved environmental impact, vibration damping, similar specific stiffness and safer handling.

Biotex Flax is available in a range of yarn weights and fabric constructions. The materials can be processed using standard composites manufacturing techniques and are suitable for semi-structural and decorative applications in a range of sectors, including automotive, sports & leisure, consumer goods and construction.

Material Benefits

Our materials use unique technologies to provide a combination of sustainability, processing and performance, offering our customers the following benefits:

Weight Reduction

Biotex Flax and Biotex Jute reinforcements are lighter than either carbon or glass fibres. Biotex Jute can be used to replace random glass fibre mats, giving a lighter product with equivalent performance and cost. Biotex Flax can be used to replace the centre layers in a carbon laminate, reducing costs and weight with no reduction in panel bending stiffness.

- Biotex Flax and Biotex Jute

- Case Study: Lightweight Stiff Door Module

- Case Study: Lightweight Sustainable Canoe

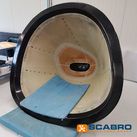

Increased Vibration Damping

Carbon fibre can cause noise, vibration and harshness (NVH) issues and has high environmental impact. Natural flax fibre composites have lower density and much higher damping than carbon fibre. By replacing some of the carbon in a laminate with flax, hybrid structures can be created with far greater damping, giving sporting goods a better feel and reducing NVH issues in vehicles.

- Biotex Flax and Biotex Jute

- Information sheet: Reducing the Cost Weight and NVH of Carbon Fibre Components by Using Flax

Reduced Component Costs

Natural flax fibre composites have lower density and lower cost than carbon fibre. Replacing some of the carbon in a laminate with flax, hybrid structures can be created with lower cost, without reduction in panel bending stiffness. Applications include automotive body panels, secondary structures, sports racquets, bike frames, hockey sticks, skis, marine bulkheads, doors etc.

- Biotex Flax and Biotex Jute

- Information sheet: Reducing the Cost Weight and NVH of Carbon Fibre Components by Using Flax

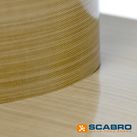

Improved Image and Aesthetics

As well as providing high-performance reinforcement, Biotex Flax and Biotex Jute reinforcements give a natural look to composite components, providing an image that is in tune with modern environmentally-conscious consumers, and appropriate to outdoor sports such as snowboarding and surfing.

- Biotex Flax and Biotex Jute

- Case Study: Durable Acoustic Guitar

- Case Study: Sustainable Biocomposite Cabinet

Reduced Environmental Impact

Biotex and Ecopreg PFA materials are derived from materials that are both sustainable and renewable. Biotex reinforcements are manufactured from Flax and Jute, both materials that have been growth for their strong fibres for centuries, whilst PFA (Polyfurfuryl Alcohol) is a bioresin derived from crop waste such as sugar cane bagasse.

- Biotex Flax and Biotex Jute

- Ecopreg Prepregs

- Case Study: Environmentally-Friendly Surfboard

- Case Study: Biocomposite Wind Turbine Blade

Enhanced Fire Performance

Ecopreg PFA prepregs are designed to have equivalent fire performance and cost as phenolic prepregs, but without the health and safety concerns of phenolic systems.

Improved Operator Health & Safety

Biotex Flax and Biotex Jute reinforcements are safe to the touch and can therefore be handled far more easily in the workplace than glass or carbon fibres. Ecopreg PFA prepregs have far lower formaldehyde and VOC emissions than equivalent phenolic materials, giving a far safer working environment.

Geen producten in deze categorie

Laatste Nieuws

-

Vacatures en stageplaatsen11/11/2023

-

Schade-inspectie van composieten09/11/2022

-

Focus on Thermoforming14/08/2021

-

Naadloze epoxypasta modellen02/11/2020