Epoxy coating met voedselkeur

- Epoxycoating die is goedgekeurd voor voedselcontact

- Bezit een uitstekende chemische weerstand

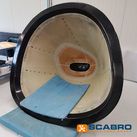

- Geschikt voor het coaten van bijvoorbeeld voedseltanks, aquaria en voedsel verwerkende ruimtes

- Vrij van benzylalcohol en droogt snel.

RESOLCOAT 4070 AL epoxy coating is formulated in replacement of older systems containing aromatic amines which no longer meet the regulatory requirements of the European Union.

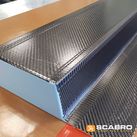

RESOLCOAT 4070 AL is a 100% dry extract anti-corrosion epoxy coating formulated to provide maximum resistance to chemicals agents. It is designed to be used as a protective liner for tanks and machinery in contact with food products.

The system has a short hardening time in film enabling fast applications and reduced down time of existing installations. It provides a smooth, non-porous high gloss finish

The RESOLCOAT 4070 AL / 4078 AL is indicated for all food grade applications. It can be applied by brush, roller or airless. Unlike other formulas containing benzyl alcohol that transmits a sour almond taste to the foods & liquids in contact, the 4070 AL guarantees a tasteless & odourless coating. It is also very little sensitive to ambient humidity and may be applied at temperatures as low as 5ºC. On porous surfaces, it is recommended to prime the surface with a coat of 150g/m² of 1010AD resin with 1015 hardener.

CURING & HARDENING

Potlife on 100g mix @ 25°C : 30 min

Polymerization on 500µm film @ 25°C : 6 h

Final drying time @ 25°C : 7 days (advised drying time before initial filling of newly coated tank) Coverage : 0,65 kg/m² for a 500µm thickness dry film per coat

APPLICATION

Although RESOLCOAT 4070 AL polymerizes perfectly starting from temperatures of 5ºC, it is preferable to mix the resin component with the hardener close to 20ºC to ease the mixing and the air releasing of the mix. The standard procedure of working with epoxy coatings applies this system.

The 4070 AL system can be applied by brush, roller, or airless gelcoater. 4070 AL has been formulated for application of 500µm without sag on vertical surfaces. Two coats are recommended.

Over coating: Its fast drying time in film will enable over coating within 4 to 8 hours. Should over coating be done after 8 hours, deglazing the surface will be necessary. Curing: 24 to 48h for optimum cure at room temperature.

It is recommended to do small mixes in flat, wide open containers as the 4070 AL / 4078 AL is very reactive. RESOLCOAT 4070 AL may be applied on any type of substrates : wood, concrete, brick, composite, metal ... as long as the surface is degreased and clean.