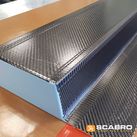

De maatgevende modelplaat voor de gieterijbranche: RAKU-TOOL® Working Board WB-1222

RAKU-TOOL® WB-1222 is de beste keuze voor negatieven, kerndozen of klopmallen voor aluminium / staal.

Kerneigenschappen

- Hoge slijtageweerstand

- Goed te frezen met lage slijtagewaarden voor het gereedschap

- Goed bestand tegen amine (gieterijwereld)

- Langere standtijd van freesgereedschap.

Applicaties

- Klopmallen

- Kerndozen, patronen voor gieterijen

- Controlemallen voor metalen onderdelen

Verkrijgbare afmetingen

- 1000 x 500 x 30 mm

- 1000 x 500 x 50 mm

- 1000 x 500 x 75 mm

- 1000 x 500 x 100 mm

Mechanische eigenschappen

| Methode | Eenheid | ||

| Kleur |

Visueel

|

Groen |

|

| Soortelijk gewicht | ISO 1183 | g/cm³ |

1.22 |

| Shore hardheid, D | ISO 868 | 75 - 80 | |

| Uitzettingscoëfficiënt | ISO 11359 |

10-6K-1 |

80 - 85 |

| Temperatuurbestendigheid (HDT) | ISO 75 | °C | 80 - 90 |

| Druksterkte | ISO 604 | MPa | 60 - 70 |

| Stijfheid | ISO 178 | MPa | 70 - 80 |

Verlijmen en repareren van RAKU-TOOL® WB-1222

RAKU-TOOL® WB-1222 is uitstekend te verlijmen en/of te repareren. De geschikte producten zijn hieronder te vinden:

- Lijmset voor RAKU-TOOL® WB-1222 en WB-1460

- Universele lijmset voor Workingboards

- Repareren gaat aan de hand van verlijmde inzetdelen, gebruik hiervoor een van de hierboven genoemde lijmsets

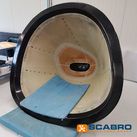

Case Study 1: RAKU-TOOL® WB-1222

Productie van een twee-delige kerndoos

Customer:

Schirm Modellbau GmbH & Co. KG, Stuttgart / Germany

Objective / Application:

Production of a core box for the manufacture of a cylinder head cover

Production process - Core box:

> Milling of core box parts from RAKU-TOOL® WB-1222

> Finishing of core box

> Insertion of air nozzles

> Trial

RAMPF Tooling Solutions Product:

The classic board RAKU-TOOL® WB-1222

> Easy and quick to machine

> Good abrasion resistance: > 15,000 parts

> Efficient – good temperature resistance as well as good impact and edge strength

> Dry ice cleaning possible

> Compatible with all paints and release agents in line with industry standards

> Already in the market since 1993

Key benefits:

> Fast production of core box through direct CNC

machining

> Limited handling of liquid systems (adhesive)

> Easy and quick changes possible

> Cost savings in comparison to metal or face cast core boxes

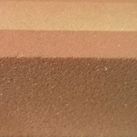

Case Study 2: RAKU-TOOL® WB-1222 board

Production of a pattern plate

Customer:

Schirm Modellbau GmbH & Co. KG, Stuttgart / Germany

Objective / Application:

Production of a pattern plate for the manufacture of a cylinder head cover

Production process - Pattern plate (lower / upper part):

> Milling of pattern from RAKU-TOOL® WB-1222

> Base plate made from hard wood with recess for pattern

> Finishing of pattern plate

> Assembly of gating system

RAMPF Tooling Solutions Product:

The classic board RAKU-TOOL® WB-1222

> Easy and quick to machine

> Good abrasion resistance: > 15,000 parts

> Efficient – good temperature resistance as well as good impact and edge strength

> Dry ice cleaning possible

> Compatible with all paints and release agents in line with industry standards

> Already in the market since 1993

Key benefits:

> Fast production of patterns through direct CNC

machining

> Limited handling of liquid systems (adhesive)

> Easy and quick changes possible

> Cost savings in comparison to metal or face cast pattern plates

Technical Datasheet (SCABRO_TDS_WB-1222.pdf, 1,181 Kb) [Download]